what tasks have been completed, and what tasks remain?

I have 2 more weeks to complete the project work. I have not started the design of the scaled down model of the Transfer Trolley I think of taking up as the project. Before that I have to complete the pending assignments which were not done due to official assignments. Hence I have to start from scratch for my final project.

what has worked? what hasn't?

Most of the assignments are done. SInce I am from Mechanical background, I have to figure out a detailed process of using the electronics in my project. The design I think of making will be feasible one as it involves 4 stepper motors. But the thing I have to think upon is to integrate an input device to control the ON-OFF of the stepper motors.

what questions need to be resolved?

There are not many queries relating to this project I am making. But the important thing to keep in mind is to include all the compulsory topics learnt in the past weeks are there in this project.

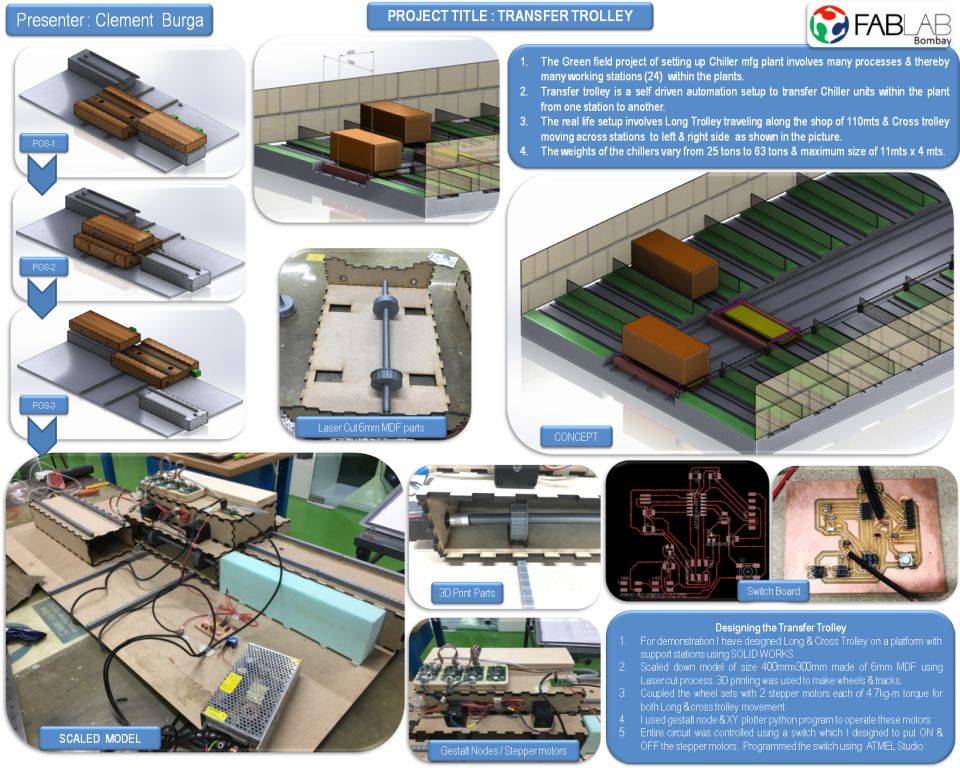

- Fabrication process - Laser cutting

- Additive machining - 3D printing

- Input Device - Switch Button

- Output device - Steppr motor using gestalt

- Embedded Programming - Program for the switch to operate the circuit

what have you learned?

I have learned things I never thought of learning in my professional career. I have learnt to work with electronics which was never my cup of tea. After I learnt to do these things it gave me a lot of satisfaction that even I can work with electronics. The next important thig I learnt was time management. I had to do my regular design work till 6pm & then come and attend the Fab class & then during the week do the assignments. In the beginning it was taking a toll on me but later realized that doing it the smart way things can be handled. This way I used to plan my regular work & the work at Fablab.

Project Slide

Below are few of the details of the project:

- The Green field project of setting up Chiller mfg plant involves many processes & thereby many working stations (24) within the plants.

- Transfer trolley is a self driven automation setup to transfer Chiller units within the plant from one station to another.

- The real life setup involves Long Trolley traveling along the shop of 110mts & Cross trolley moving across stations to left & right side as shown in the picture.

- The weights of the chillers vary from 25 tons to 63 tons & maximum size of 11mts x 4 mts.